Getting the arch right is important for the overall look of the oven. Brick arches are used to span the entrance to the oven, creating that great looking curved front entrance and retaining the flue entry.

The arch needs to be curved to transfer vertical loads laterally. The Romans mastered this science, but for us this can be one of the trickiest parts of the oven build. Once mortared in place a brick should not be moved after about 30 seconds or the initial bond between the mortar and the brick can be broken leading to cracks and structural failure. This becomes very tricky for a beginner arch maker!

Our arch templates and recommended mortar products are designed to simplify this step. Instead of building the arch brick by brick, which is fraught with error and difficulty, the arch is pre-built using packers over a template then mortar is added afterwards. The bricks are sized for a perfect fit. No cutting required. Too easy!

We recommend the use of fire bricks for the arch as the area becomes hot around the flue entry and the last thing you want is cracked (or spalling) front arch bricks destroying the look of your oven. These bricks come pre-formed in a tapered brick which looks significantly better than using a standard shaped brick.

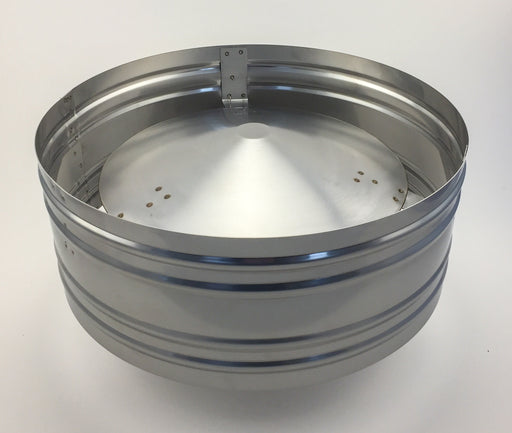

Cardboard moulds demonstrating the arch build

In this first model the dome is created first then the arch bricks are put in place later once the cardboard mould has been removed.

In this model the arch bricks are added before the mortar is added. The oven is poured as one