The flue is a duct or pipe for conveying exhaust fumes from the oven. For convenience, the flue is usually a pre-made piece of stainless steel pipe but it can also be constructed using fire bricks or a combination of both.

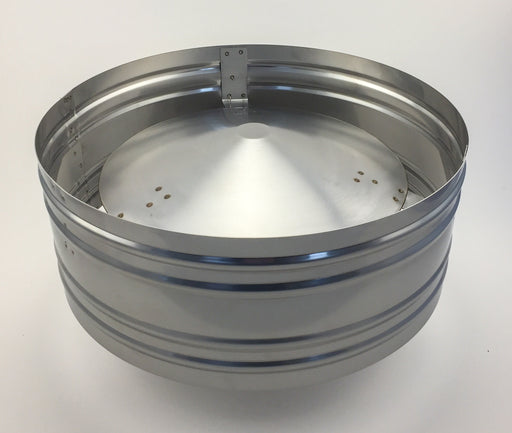

A typical section of flue. Note the corrugations at the bottom to reduce pipe diameter allowing it to slot into the starter ring or other sections of flue

The pipe comes in different diameters (usually 100mm to 250mm) and lengths (usually 600mm to 1200mm). We have a few options in our shop. To hold the flue in place a starter ring or transition section is normally built into the area where the oven entrance meets the dome.

As starter ring set in place on the cardboard mould prior to mortar being applied

The flue starts to work when the air inside the flue heats up, and through convection (hot air rising), draws or ‘sucks’ the fumes out of the oven before it can exit through the front oven entrance (and into your face!). Until the air inside the flue is rising (i.e. when it's warm) it won't draw properly which is why an oven or fire can billow smoke out the front until this happens.

While it draws hot air up the convection process pulls cooler oxygen rich air into the fire chamber to help combustion. (See diagram in how pizza ovens work)

Hint: If you have a long flue system, lighting a small piece of paper directly under the flue when starting the fire can help it start drawing.

Flues in standard fireplaces can be quite complex and their length and diameter can greatly alter the performance of a fire. With pizza ovens it is not quite as critical. Plenty of ovens are built with no flue at all, with exhaust fumes simply pouring out the front. This option isn't much fun when cooking a pizza as smoke billows in your face and it's much nicer to direct smoke away from your captivated audience.

We recommend a 150mm diameter flue. It balances a good draw with that ‘chunky’ look.

Flue expansion

One of the key issues with the flue being metal, is that it expands when heated. Being secured in by mortar (which expands at a lesser rate) it can tend to cause this surrounding mortar to crack. Whilst cracks may not make the oven structurally unsafe, they can lead to water ingress and further hydraulic cracking (cracking from steam).

To alleviate this, insulation is wrapped around the base of the flue to help isolate the mortar from the flue heat and allow room for the flue to expand as it heats up.

Above the insulation layer, mortar will be laid hard against the flue to hold it in place, shape the oven and protect the insulation from the elements.

Our higher end kit sets utilise a novel twin flue system which helps alleviate heat pressure. It is like a double glazed window. The inner flue, which is in direct contact with the heat exiting the fire, gets a lot hotter than the outer flue so expansion pressure is lessened (= less cracks). There are detailed instructions on how to build this system provided with the kits.

You may see manufacturers supply ovens with preformed flue transitions (such as ceramic collars) which is a great solution but it is an expensive option. We prefer keeping it simple.

Double flue system reduces cracking and insulation wrapped around the base of flue before mortar is applied

See our range of flues and accessories here

A few notes of caution regarding flues:

Pizza ovens (and outdoor fires) with too large a diameter flue or too long a flue can draw too much heat out of your oven. It can make your oven slower to heat up and recover whilst cooking. You end up using more wood.

Using too small a diameter flue means not enough smoke is drawn up and away, diminishing your cooking experience.

Also be careful of the overall height of the flue above the oven as too high a flue can attract the need for council consent.

Don't use galvanised flue. It might be cheaper, but the galvanising won't last with the heat and will soon look rusty and horrible. It's not designed for high heat applications.