This is a very important and poorly understood area of pizza ovens.

There are three main aspects to consider in floor design:

- Isolating the floor fire bricks (cooking surface) from the concrete hearth to avoid unnecessary heat loss

- Establishing a thermal heat bank to retain heat for better cooking

- Protecting your concrete hearth from the intense heat generated from the fire

Portland cement (the key ingredient to making the concrete hearth) has relatively low temperature tolerances in comparison to refractory materials. It is not able to withstand the high oven temperatures. If subjected to a great deal of heat, standard concrete becomes unstable and experiences mechanical and structural failure. If there is moisture trapped the hearth, this heat can also cause explosive spalling.

We therefore need to add materials on top of the hearth before constructing the oven dome to both protect it and enhance the cooking performance.

The diagram below illustrates what happens when there is no insulation between the fire brick floor and the concrete hearth. Excessive heat is transferred into the concrete.

Recognising the importance of retaining the heat in the floor, we need to consider that when food (like pizza) is placed on the fire brick floor, the energy stored in the bricks is transferred via convection to cook the base. The heat energy in the bricks is quickly depleted and must be recharged. The total density of your floor therefore becomes important (i.e. its ability to retain enough heat).

It is also important that the floor of the oven is balanced with the rest of the oven. For example, if a floor is too thick in comparison with the rest of the oven, then it takes too long to heat up properly after the rest of the oven is ready.

With this in mind, there are two main ways to plan the floor.

- Either combine fire bricks with a refractory underlay (heat bank) or

- Use thicker fire bricks capable of retaining enough heat in themselves.

For both methods, it is essential to use insulation.

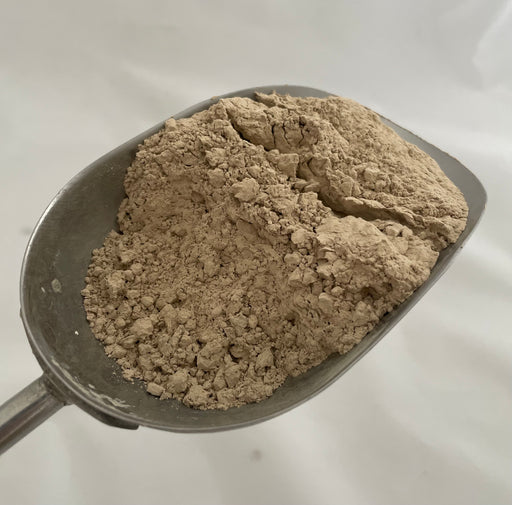

1: Combining fire bricks with a heat bank

This construction technique involves laying the fire bricks on a base of refractory mortar on top of the insulation layer. This base layer provides additional density (so heat storage) but it also allows for the fire bricks to be laid flat and level against one another. Fire bricks usually vary in thickness, so rather than mechanically levelling (grinding) the bricks after they are laid (a terrible job), a flat floor surface is achieved when the bricks are laid.

Thinner fire bricks (like 25mm and 40mm) can be used making cutting to shape a lot easier. 75mm thick bricks are difficult to cut with basic tools.

See the construction summary video here

Illustrating the refractory bedding layer helping to retain heat in the oven and 'recharge' the cooking fire brick floor above.

2: Using just fire bricks

Using this method the fire bricks are placed straight onto the insulation (aluminium foil is usually placed between them). 75mm thick fire bricks are usually used in this instance. The main difficulty is getting the fire bricks level and cutting the thicker bricks (fire bricks are a lot harder to cut than traditional bricks due to their density).

Bear in mind even small height differentials in bricks can catch pizza peals and tools so it becomes important.