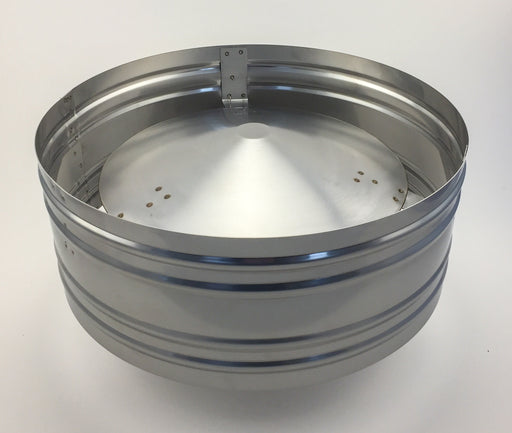

The inner dome needs to be able to cope with the extreme heat generated by burning wood. Its job is to soak up heat from the fire and radiate this back towards the food over the desired cooking period. The thicker and more dense this material is the longer it will take to heat up (as it absorbs more heat) but also the longer it will radiate heat (as more heat is stored).

Castable refractories

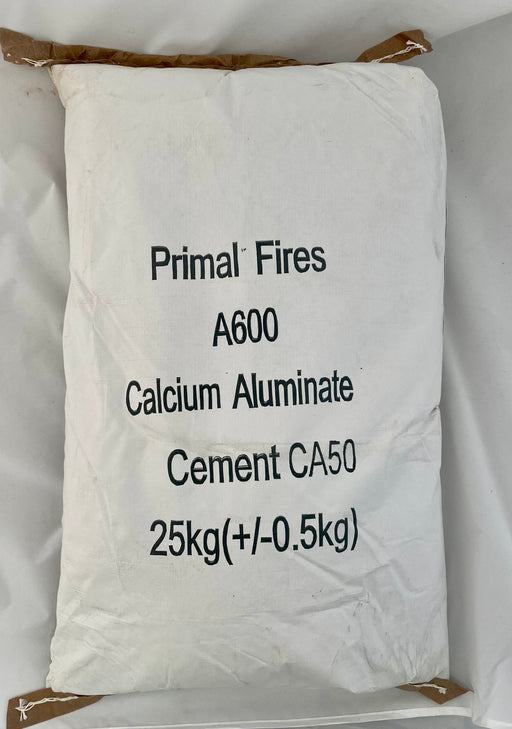

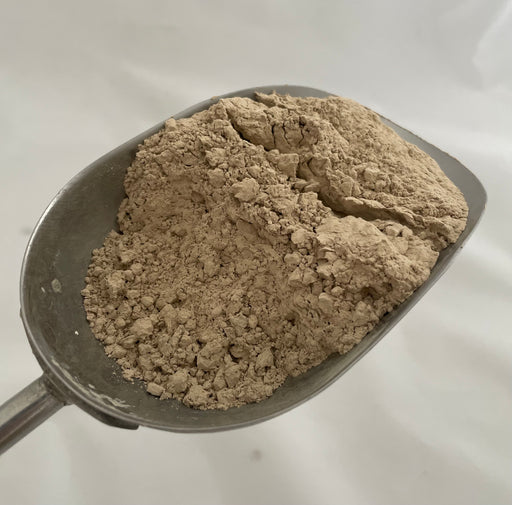

There is a range of modern refractory materials available that can withstand the high oven temperatures. They are commonly referred to as refractory castable materials. These are mixed with water (similar to concrete) and 'caste' or shaped to the desired form.

This is the more modern way of building inner domes. Whilst the technology has been around for a while, it is only more recently that these products have been used in pizza ovens.

Refractory castables are dense and durable, but most importantly are very easy to apply into or over a mould. By adjusting the thickness you can create a tailored level of performance. The thicker the material the greater its heat retention capacity but the longer it will take to heat up. The ease of use, performance and value, certainly make these materials our pick for oven construction.

This is where our cardboard moulds come into their own. The whole oven dome, arch, entrance and flue gallery can be created in one application of mortar. It really is genius.

Castable Refractory concrete being applied over cardboard mould

Insulation type materials

For example perlite, vermiculite or pumice in concrete mortar or brick form.

Using an insulation type material (like perlite) for the inner dome simple means the oven will not soak up as much heat energy as an oven constructed of denser material. The oven will heat up fast but also cool down quickly, as it doesn't have the density to store heat. To cook a pizza or roast, this sort of oven relies on having a ‘live fire’ to provide most of the required heat. With that said, an oven that heats up quickly can make it a a lot more usable at short notice and it will use less fuel so its worth considering.

These materials are usually quite economical to use but don't be tempted to use standard Portland cement with them. You must use refractory cement!

Perlite pictured in raw and concrete form

Refractory fire bricks

This type of brick is the more traditional choice for building ovens and are usually manufactured using compression to achieve the desired density.

They are durable and retain heat well, but they require considerable bricklaying skills to build with, are quite expensive and must be used in conjunction with specialist mortars. Thick brick layers can also lead to longer oven start up times as more heat is required to get the bricks to the correct temperature. This can be quite wasteful if you are just cooking a few pizzas.