Featured collection

Fire Bricks 230 x 115 x 25mm, Lot of 16 Bricks

Primal FiresThis is a for a stack of 16 bricks These high density refractory fire bricks are ideal for use as a floor in an oven or for walls and floor in a f...

View full details800mm Pizza Oven Building Kit - Primal Premium 800 Pack

Primal FiresThis kit includes everything you need to build an 800mm dome diameter pizza oven once you have built the concrete slab (hearth) for it to sit on....

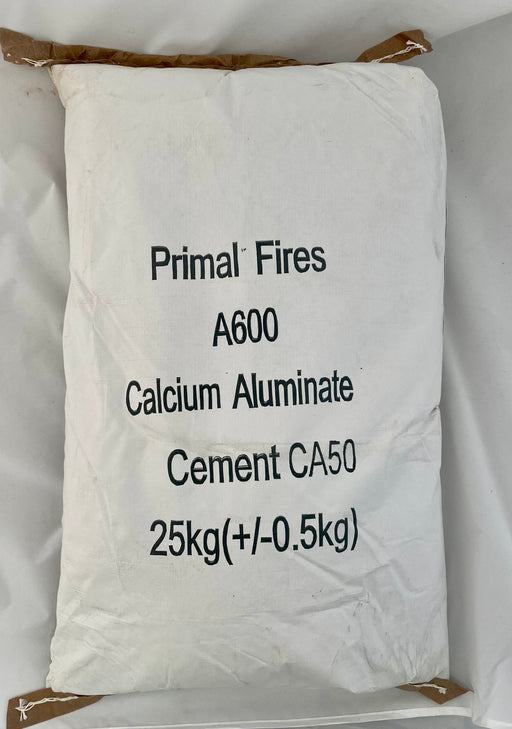

View full detailsCalcium Aluminate Cement (refractory cement) 25kg

Primal FiresCalcium aluminate cement is very popular choice for making up your own refractory castable mix's and mortars for high temperature applications. Th...

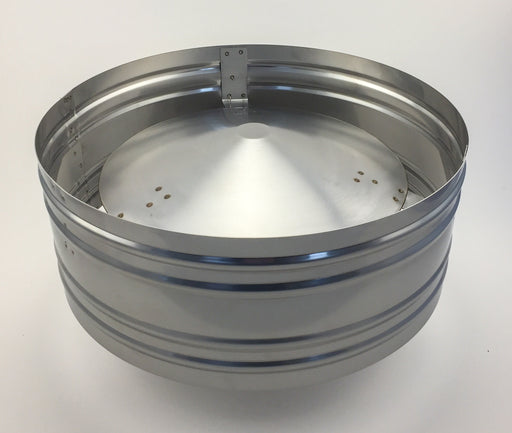

View full detailsAnti Downdraft Cowl (Rain Cap) Five sizes Available

Primal FiresThis is a high quality stainless steel anti downdraft cowl. The bottom spigot (piece of pipe on the bottom) is designed to sit inside a flue pipe. ...

View full detailsCeramic Fibre Blanket 128kg/M3, 25mm thick x 610mm wide x 7.62m long Full Roll

Primal FiresThese ceramic fibre blankets are brilliant for use in high temperature environments and are ideal for oven and fire building applications. Applyin...

View full details